MC-II PULSE BAG FILTER

- Description

Description

MC-II pulse injection bag filter is a type of the bag filter, with compressed air as deashing power. The filter makes use of the pulse injection mechanism to instantaneously release the compressed air, induces several times of the secondary air to inject into the filter bag at a high speed, making the filter bag swell rapidly, and relies on impulse and airflow direction for deashing.

MC-II pulse bag filter is a new type of efficient dedusting purification equipment, adopting low-pressure pulse injection as the deashing method, so that the service life of the pulse valve and the filter bag can be 1 time longer than the original or more. At the same time, it has many advantages such as good deashing effect, high purification efficiency, large processing capacity, small maintenance load, safe and reliable operation, etc.

The pulse injection bag filter is widely used for dedusting purification of industrial non-fibrous dust in various industrial and mining enterprises, such as coking plant, refractory, metallurgy, building materials, chemical industry, food, mining machinery, agricultural chemicals and electronic products.

- Basic Structure

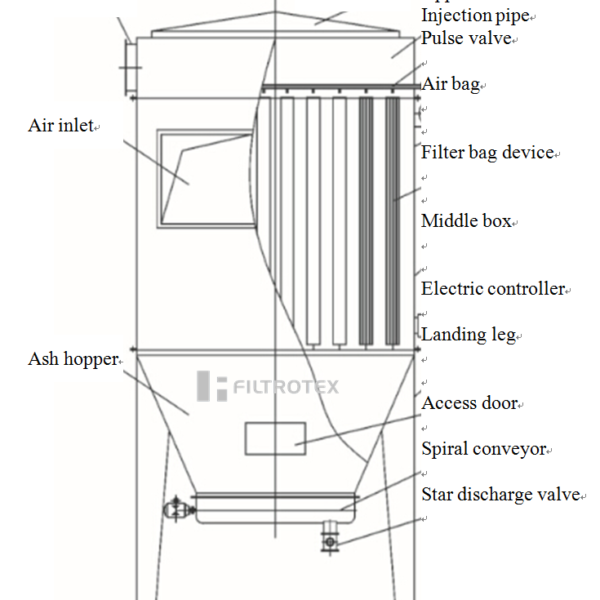

MC-II pulse injection bag filter is composed of five parts, i.e. the upper, middle and lower boxes, ash discharge system and injection system. The upper box consists of uplift cover plate and outlet; the middle box consists of tube sheet, filter bag device; the lower box is composed of ash hopper, air inlet and access door; the injection system consists of pulse controller, pulse valve, injection pipe and air bag.

- Basic Structure

Dusty gas enters into the lower box from the air inlet, and becomes net gas after passing through the filter bag. Net gas enters into the upper box through a Venturi tube, and then is discharged from the outlet. Dust accumulated on the surface of the filter bag is increasing, so the resistance of the filter increases. In order to maintain equipment resistance within the specified scope (generally, 1.2-1.5Kpa), dust on the surface of the filter bag should be removed. When deashing, each pulse valve is regularly triggered by the controller in order, to make compressed air in the air bag eject (primary air) through the injection pipe, at the same time, air (secondary air) around several times of primary air is induced into the filter bag through Venturi tube. Thus the filter bag swells up in a sudden, and shakes off dust along with the reverse directive effect of airflow. Then dust falls into the ash hopper, and is discharged through the ash discharge valve.